FULL FLOW Normally Closed with threaded ports

PISTON VALVES

pressure operated2- and 3-Way, Normally Closed with threaded ports, PN32, DN 8 - 40

FEATURES

- Ruggedly built valve, particularly recommended for use with steam, oil, superheated water, corrosive fluids and non-flammable gas.

- Seat rings, packing and piston seals can be easily exchanged. Replacing a piston seal is considerably easier and quicker then exchanging a diaphragm on conventional diaphragm valves

- Enclosed pistons, seals and springs are protected from dirt

- High-performance, self-adjusting, spring-loaded, maintenance-free packing, resistant to thermal shock

- Vacuum operation

- Stainless steel body.

- Allowable backpressure: up to 32 bar.

- Valve for use at high ambient temperatures (up to 180°C).

- The valves can be mounted in any position without affecting operation

PRODUCT ADVANTAGES:

Compact Design

Self-Regulating Packing

Non-Corrosive Materials

High sealing effect

Long Life

Universally for all Mediums

Easy Maintenance

High Performance

Robust Design

Compact Design

Self-Regulating Packing

Non-Corrosive Materials

High sealing effect

Long Life

Universally for all Mediums

Easy Maintenance

High Performance

Robust Design

GENERAL INFORMATION:

scrollable table

| Maximum operating pressure: | 32 bar |

| Temperature range: | – 30 °C to + max. 230 °C |

| Pilot pressure: | 2,5 – 3,5 bar |

| Operating fluids: | Steam / Saturated Steam, Superheated Water, Gases, Vacuum |

FLOW RATES – P3W Series:

| Model Number | Pipe Size | DN | Flow coefficient Kv | |||||||

| mixer | distributor | |||||||||

| 3 “ 2 | 1 “ 2 | 2 “ 3 | 2 “ 1 | |||||||

| m3/h | l/min | m3/h | l/min | m3/h | l/min | m3/h | l/min | |||

| NC – Normally Closed | ||||||||||

| P3W-BSPT1-10A | ⅜” | 10 | 1,8 | 30 | 1,93 | 32,17 | 1,67 | 27,84 | 2,18 | 36,34 |

| P3W-BSPT1-15A | ½” | 15 | 3,47 | 57,85 | 3,5 | 58,35 | 3,46 | 57,68 | 3,6 | 60 |

| P3W-BSPT1-20A | ¾” | 20 | 7,06 | 117,7 | 5,31 | 88,52 | 7,33 | 122,19 | 5,13 | 85,52 |

| P3W-BSPT1-25A | 1″ | 25 | 13,9 | 231,7 | 9,2 | 153,36 | 10,73 | 178,87 | 9,63 | 160,53 |

| P3W-BSPT1-32A | 1¼” | 32 | 20,6 | 343,4 | 15,1 | 251,72 | 17,1 | 285,06 | 16,1 | 268,4 |

| P3W-BSPT1-40A | 1½” | 40 | 25,1 | 418,42 | 18,31 | 305,23 | 20,92 | 348,74 | 18,9 | 315,06 |

scrollable table

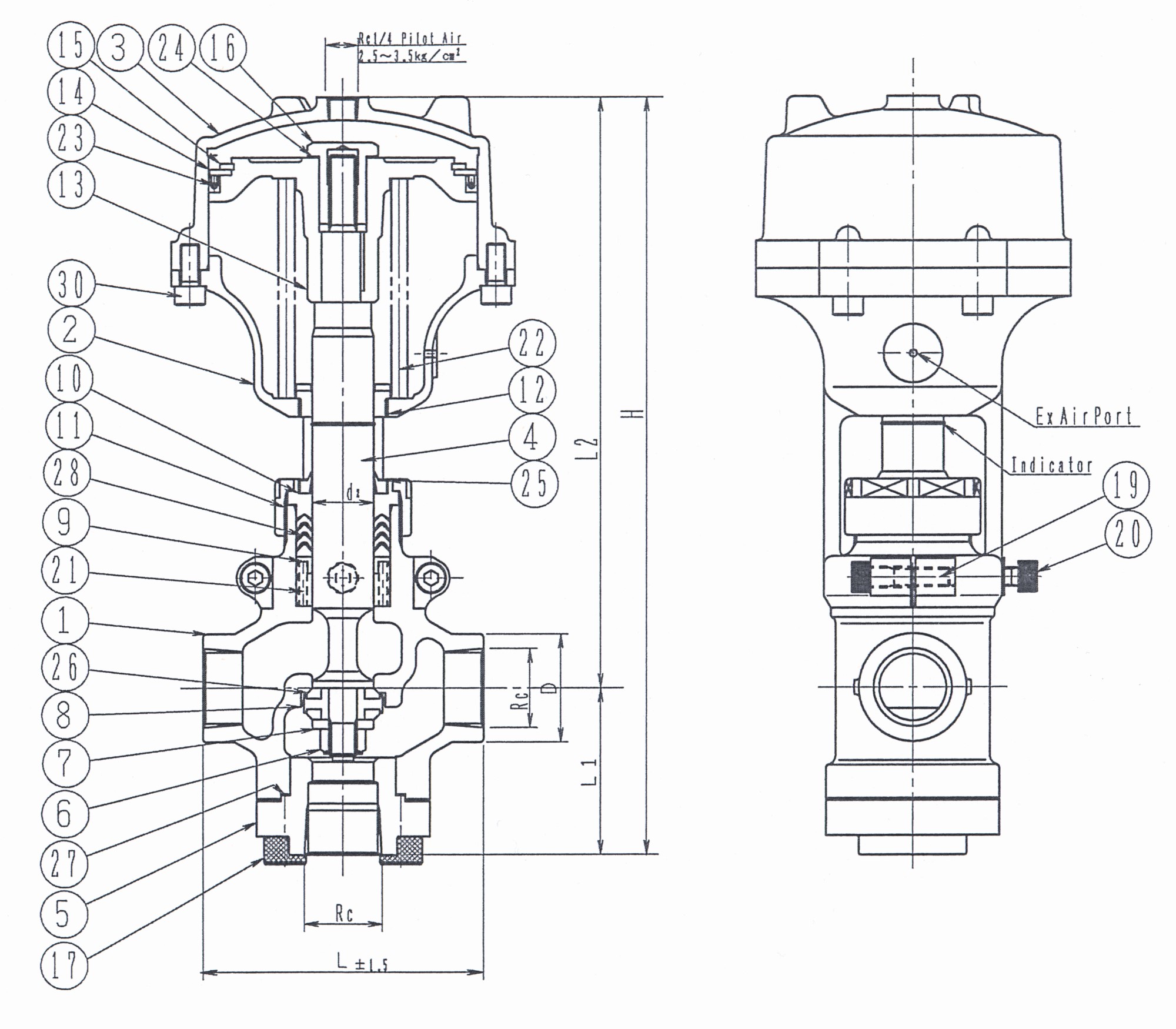

| No. | Part Name | Materials | No. | Part Name | Materials |

| 1 | Body | SCS13 = 1.4308 | 16 | Tension Nut | S25C = 1.1158 |

| 2 | Yoke Stand | FCD450 = GGG-40.3 | 17 | Cap Screw | SUS304 = 1.4301 |

| 3 | Cylinder | FCD450 = GGG-40.3 | 18 | ||

| 4 | Stem | SUS403 = 1.4000 | 19 | Cap Screw | SUS304 = 1.4301 |

| 5 | Lower Seat Flange | S25C = 1.1158 | 20 | Cap Screw | SUS304 = 1.4301 |

| 6 | U-Nut | SUS304 = 1.4301 | 21 | Packing Spring | SUS304-WPB |

| 7 | Guide Washer | SUS304 = 1.4301 | 22 | Spring | SUP6 |

| 8 | Disc Adapter | SUS304 = 1.4301 | 23 | Piston Ring | Teflon (PTFE) |

| 9 | Ring Washer | C3602 – Brass | 24 | Gasket | 562-1 |

| 10 | Gland | C3602 – Brass | 25 | Dust Seal | SUS304 + 763-1 |

| 11 | Gland Nut | S25C = 1.1158 | 26 | Disc Ring | Teflon (PTFE) |

| 12 | Guide Bushing | C3602 – Brass | 27 | Lower Seat Gasket | 562-1 |

| 13 | Piston | FCD450 = GGG-40.3 | 28 | Packing | 763-1 |

| 14 | Set Ring Plate | SS400 | 29 | Bolt | SUS304 = 1.4301 |

| 15 | Retaining Ring | S60CM | 30 | Cap Screw | SUS304 = 1.4301 |

Model Selection / Dimensions:

scrollable table

| Model Number | Rc / BS-PT | D | L | L1 | L2 | H | A | d2 | Weight, kg | |

| 2-Way | 3-Way | |||||||||

| P2W-BSPT1-08A | P3W-BSPT1-08A | ¼” | 30 | 85 | 50 | 165 | 215 | 98 | 12.7 | 2.8 |

| P2W-BSPT1-10A | P3W-BSPT1-10A | ⅜” | 30 | 85 | 50 | 165 | 215 | 98 | 12.7 | 2.8 |

| P2W-BSPT1-15A | P3W-BSPT1-15A | ½” | 32 | 85 | 50 | 196 | 246 | 109 | 15 | 3.8 |

| P2W-BSPT1-20A | P3W-BSPT1-20A | ¾” | 40 | 110 | 66 | 230 | 296 | 136 | 19 | 6.6 |

| P2W-BSPT1-25A | P3W-BSPT1-25A | 1″ | 46 | 120 | 71 | 250 | 321 | 156 | 26 | 9.8 |

| P2W-BSPT1-32A | P3W-BSPT1-32A | 1¼” | 56 | 145 | 92 | 295 | 387 | 202 | 34 | 15.6 |

| P2W-BSPT1-40A | P3W-BSPT1-40A | 1½” | 62 | 150 | 92 | 295 | 387 | 202 | 34 | 15.6 |